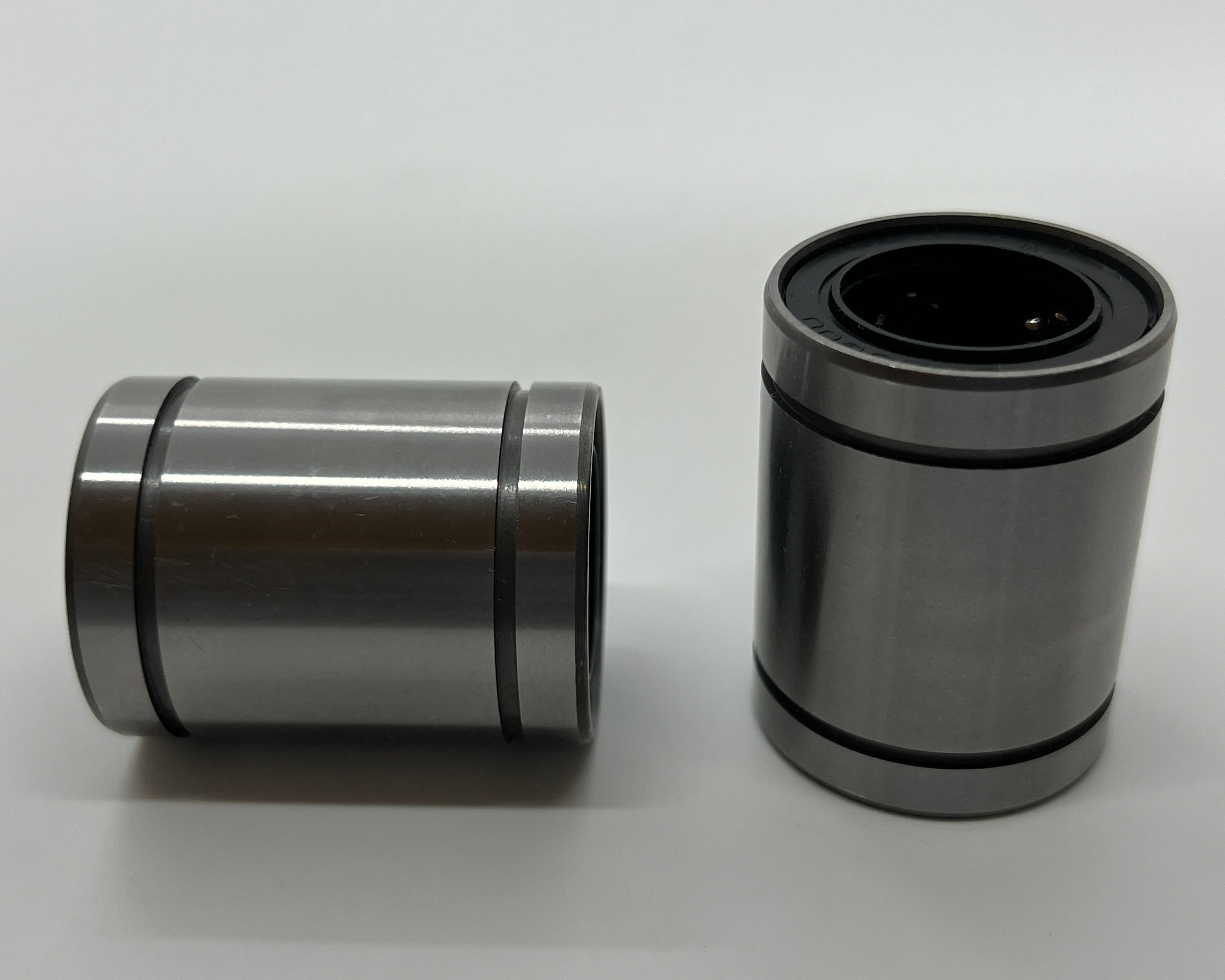

Linear Guide Rails in India: A Comprehensive Guide for Buyers Linear guide rails, or linear motion guides or Linear bearings, are crucial components in various industrial machinery and automation systems. They provide smooth, precise, and low-friction linear motion, contributing significantly to the efficiency and accuracy of multiple applications. For businesses and engineers in India looking to procure linear guide rails, understanding the different types, key specifications, and local market dynamics is essential for making informed purchasing decisions. This article serves as a comprehensive guide for buyers in India. It offers valuable insights and incorporates relevant SEO keywords to enhance its online visibility. Understanding Linear Guide Rails At their core, linear guide rails consist of two main parts: Rail (or Shaft): A precisely machined steel or aluminium profile with hardened raceways. Block (or Carriage): A bearing unit slides along the rail, typically incorporating recirculating ball or roller bearings. These components facilitate linear movement with minimal friction and high load-bearing capacity. Types of Linear Guide Rails Available in India The Indian market offers a variety of linear guide rail types to cater to diverse application requirements. Some of the most common types include: Ball-Type Linear Guide Rails: These are the most prevalent type, utilizing recirculating steel balls between the rail and the block. They offer good load capacity, high-speed capability, and smooth movement. They are widely used in CNC machines, automation equipment, and general industrial machinery. Roller-Type Linear Guide Rails: These guides employ cylindrical or needle rollers instead of balls. They provide higher load capacity and rigidity than ball-type guides, making them suitable for heavy-duty applications like large machine tools and industrial robots. Miniature Linear Guide Rails: Compact and lightweight, these guides are designed for precision applications with limited space, such as semiconductor manufacturing equipment, medical devices, and small robotic arms. Profiled Rail Guides: These feature precise ground profiles on the rail and the block, offering high accuracy and rigidity. They are commonly used in high-precision CNC machining centres and measuring instruments. Round Shaft Linear Bearings consist of hardened and ground round shafts and linear ball bearings or bushings. They are a more cost-effective option for lighter-load applications and are often used in simpler automation setups. Key Factors to Consider When Buying Linear Guide Rails in India When selecting linear guide rails for your application in India, several critical factors need careful consideration: Load Capacity: Determine the maximum static and dynamic loads the guide rails need to support. Consider factors like the weight of the moving components and any external forces. Accuracy and Precision: The required level of accuracy depends on the application. Opt for profiled rail guides with tight tolerances for high-precision tasks like CNC machining. Travel Length: Ensure the selected rail length accommodates your application's full range of motion. Standard lengths are available, and custom lengths can often be ordered. Speed and Acceleration: Consider the maximum speed and acceleration the system will experience. Different guide rail types have varying speed limitations. Rigidity: Rigidity is crucial for maintaining accuracy under load. Roller-type and profiled rail guides generally offer higher rigidity. Operating Environment: Consider the operating conditions, including temperature, dust, and humidity. Choose materials and seals that can withstand the environment. Maintenance Requirements: Evaluate the ease of lubrication and maintenance. Some guide rails come with integrated lubrication systems. Cost: Balance the performance requirements with your budget. Ball-type guides are generally more cost-effective than roller-type or profiled rail guides. Round shaft linear bearings offer the most economical solution for lighter loads. Supplier Reliability and Support: Choose a reputable supplier in India who can provide technical support, application guidance, and after-sales service. Consider factors like lead times and spare parts availability. Finding Linear Guide Rail Suppliers in India India has a growing market for linear motion components, with numerous domestic and international manufacturers and suppliers. You can find suppliers through various channels: Online Marketplaces: Platforms like IndiaMART, TradeIndia, and www.ibizkart.com list numerous linear guide rail suppliers. Industrial Exhibitions and Trade Shows: Attending events focused on manufacturing, automation, and machine tools can provide direct opportunities to connect with suppliers.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Linear Guide Rails in India: A Comprehensive Gu...

2025-04-09T02:58:23

Linear Guide Rails in India: A Comprehensive Guide for Buyers Linear guide rails, or linear motion guides or Linear bearings, are crucial components in various industrial machinery and automation systems. They provide smooth, precise, and low-friction linear motion, contributing significantly to the efficiency and accuracy of multiple applications. For businesses and engineers in India looking to procure linear guide rails, understanding the different types, key specifications, and local market dynamics is essential for making informed purchasing decisions. This article serves as a comprehensive guide for buyers in India. It offers valuable insights and incorporates relevant SEO keywords to enhance its online visibility. Understanding Linear Guide Rails At their core, linear guide rails consist of two main parts: Rail (or Shaft): A precisely machined steel or aluminium profile with hardened raceways. Block (or Carriage): A bearing unit slides along the rail, typically incorporating recirculating ball or roller bearings. These components facilitate linear movement with minimal friction and high load-bearing capacity. Types of Linear Guide Rails Available in India The Indian market offers a variety of linear guide rail types to cater to diverse application requirements. Some of the most common types include: Ball-Type Linear Guide Rails: These are the most prevalent type, utilizing recirculating steel balls between the rail and the block. They offer good load capacity, high-speed capability, and smooth movement. They are widely used in CNC machines, automation equipment, and general industrial machinery. Roller-Type Linear Guide Rails: These guides employ cylindrical or needle rollers instead of balls. They provide higher load capacity and rigidity than ball-type guides, making them suitable for heavy-duty applications like large machine tools and industrial robots. Miniature Linear Guide Rails: Compact and lightweight, these guides are designed for precision applications with limited space, such as semiconductor manufacturing equipment, medical devices, and small robotic arms. Profiled Rail Guides: These feature precise ground profiles on the rail and the block, offering high accuracy and rigidity. They are commonly used in high-precision CNC machining centres and measuring instruments. Round Shaft Linear Bearings consist of hardened and ground round shafts and linear ball bearings or bushings. They are a more cost-effective option for lighter-load applications and are often used in simpler automation setups. Key Factors to Consider When Buying Linear Guide Rails in India When selecting linear guide rails for your application in India, several critical factors need careful consideration: Load Capacity: Determine the maximum static and dynamic loads the guide rails need to support. Consider factors like the weight of the moving components and any external forces. Accuracy and Precision: The required level of accuracy depends on the application. Opt for profiled rail guides with tight tolerances for high-precision tasks like CNC machining. Travel Length: Ensure the selected rail length accommodates your application's full range of motion. Standard lengths are available, and custom lengths can often be ordered. Speed and Acceleration: Consider the maximum speed and acceleration the system will experience. Different guide rail types have varying speed limitations. Rigidity: Rigidity is crucial for maintaining accuracy under load. Roller-type and profiled rail guides generally offer higher rigidity. Operating Environment: Consider the operating conditions, including temperature, dust, and humidity. Choose materials and seals that can withstand the environment. Maintenance Requirements: Evaluate the ease of lubrication and maintenance. Some guide rails come with integrated lubrication systems. Cost: Balance the performance requirements with your budget. Ball-type guides are generally more cost-effective than roller-type or profiled rail guides. Round shaft linear bearings offer the most economical solution for lighter loads. Supplier Reliability and Support: Choose a reputable supplier in India who can provide technical support, application guidance, and after-sales service. Consider factors like lead times and spare parts availability. Finding Linear Guide Rail Suppliers in India India has a growing market for linear motion components, with numerous domestic and international manufacturers and suppliers. You can find suppliers through various channels: Online Marketplaces: Platforms like IndiaMART, TradeIndia, and www.ibizkart.com list numerous linear guide rail suppliers. Industrial Exhibitions and Trade Shows: Attending events focused on manufacturing, automation, and machine tools can provide direct opportunities to connect with suppliers.

2025-04-09T02:58:23

Keywords

- india india

- find suppliers

- critical factors

- load rollertype

- costeffective option

- precision applications

- crucial components

- manufacturing automation

- indiamart tradeindia

- international manufacturers

- numerous domestic

- lead times

- aftersales service

- reputable supplier

- support choose

- economical solution

- temperature dust

- operating conditions

- maintaining accuracy

- maximum speed

- ordered speed

- highprecision tasks

- tight tolerances

- application opt

- accuracy depends

- required level

- dynamic loads

- maximum static

- limited space

- needle rollers

- minimal friction

- aluminium profile

- article serves

- automation systems

- industrial machinery

- lighterload applications

- heavyduty applications

- multiple applications

- moving components

- roller bearings

- comprehensive guide

- performance requirements

- custom lengths

- smooth movement

- growing market

- common types

- guide rails

- machine tools

- linear bearings

- hardened raceways block

- guide rail types

- diverse application requirements

- linear guide rails

- profiled rail guides

- external forces accuracy

- large machine tools

- linear motion components

- linear ball bearings

- applications full range

- main parts rail

- humidity choose materials

- motion standard lengths

- provide smooth precise

- linear motion guides

- budget balltype guides

- balltype guides making

- guides employ cylindrical

- indian market offers

- local market dynamics

- types key specifications

- provide direct opportunities

- ground round shafts

- bearing unit slides

- precisely machined steel

- offers valuable insights

Search on this site

Have any question or need any business consultation?

Have any question or need any business consultation?

Contact UsIBK ENGINEERS Pvt Ltd

Submit Your Enquiry