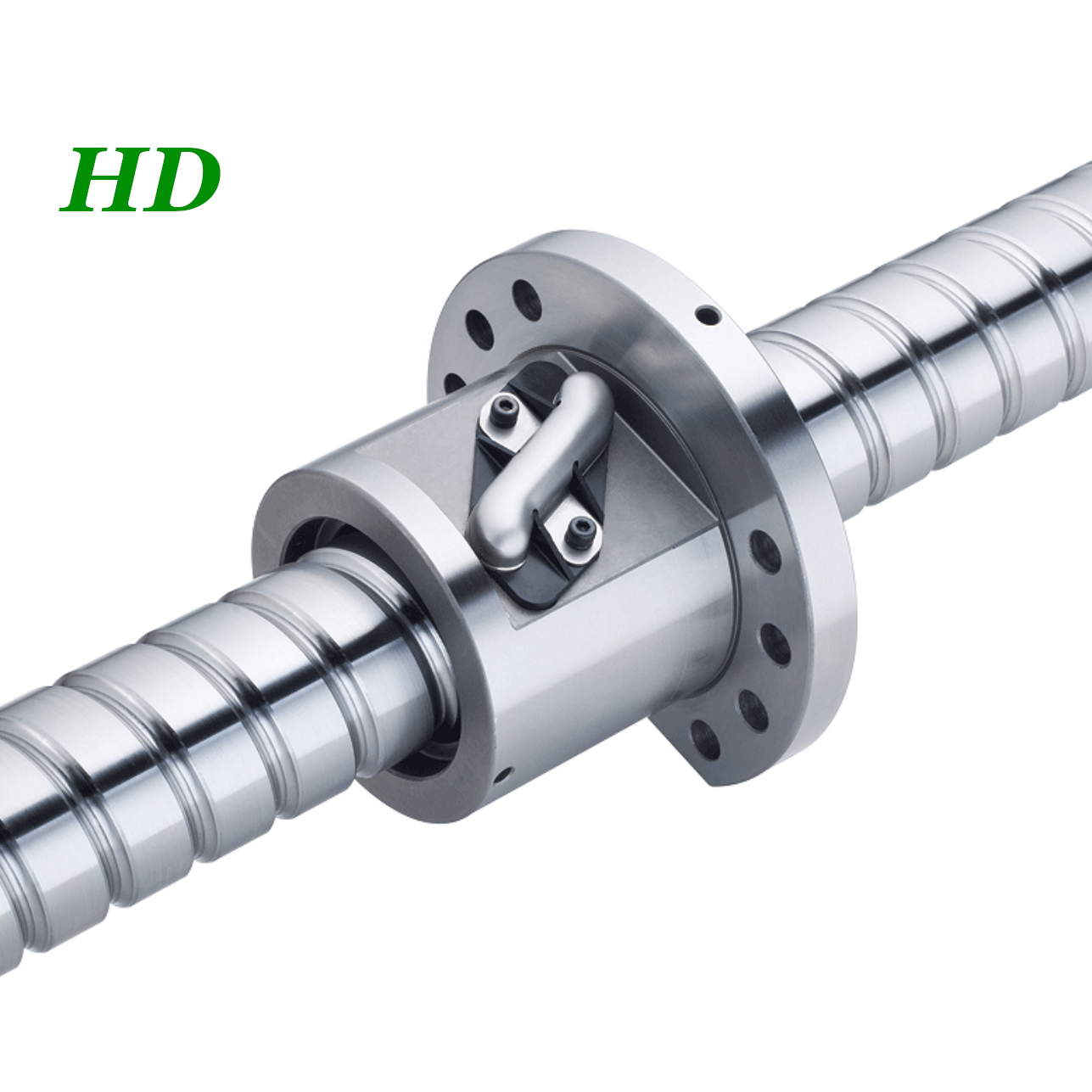

Ball Screws in India: A Comprehensive Guide for Buyers in 2025 Ball screws are precision mechanical components that convert rotary motion into linear motion, or vice versa, with high efficiency and accuracy. They are integral to various industrial machinery and automation systems, playing a crucial role in applications demanding precise positioning, high load capacity, and smooth operation. For businesses and engineers in India seeking to procure ball screws in 2025, a thorough understanding of the different types, key specifications, selection criteria, and the evolving Indian market landscape is paramount for making informed purchasing decisions. This comprehensive article serves as a valuable resource for buyers in India. It provides in-depth information and incorporates relevant SEO keywords to enhance its online visibility and reach the target audience. Understanding the Fundamentals of Ball Screws A ball screw assembly primarily consists of four main components: Screw Shaft: A precision-machined steel shaft with a helical groove (ball track) ground along its length. Nut: A housing with internal helical grooves that match the screw shaft's grooves. It contains the ball bearings. Ball Bearings: Precision steel balls that circulate between the grooves of the screw shaft and the nut, providing the rolling contact that minimizes friction. Ball Return Mechanism: A system within the nut that guides the balls back to the track's starting point after they have travelled the length of the nut. Common types include internal and external return tubes, deflectors, and end caps. The rolling motion of the balls between the screw and the nut significantly reduces friction compared to traditional lead screws, resulting in higher efficiency, lower power consumption, and reduced wear. Types of Ball Screws Available in the Indian Market (2025) The Indian market in 2025 offers a diverse range of ball screw types to cater to the specific needs of various industries. Key types include: Ground Ball Screws: These are manufactured by precision grinding the ball tracks on both the screw shaft and the nut. They offer the highest accuracy, repeatability, and preload capabilities, making them ideal for high-precision applications such as CNC machine tools, measuring instruments, and semiconductor manufacturing equipment. Ground ball screws are typically more expensive due to the intricate manufacturing process. Rolled Ball Screws: These are produced by a rolling process, which is more cost-effective than grinding. While they offer good accuracy and load capacity, their precision levels are generally lower than ground ball screws. Rolled ball screws are widely used in general automation equipment, packaging machinery, and less demanding positioning systems where cost-effectiveness is a significant factor. Miniature Ball Screws: These compact and lightweight ball screws are designed for applications with limited space and weight constraints, such as small robotic arms, medical devices, and precision instruments. They offer high precision in a small form factor. High Lead Ball Screws: These screws have a larger helix angle, resulting in a greater linear travel per revolution of the screw shaft. They are suitable for applications requiring high-speed and rapid traverses, such as pick-and-place robots and high-speed automation systems. However, they may have lower load capacity compared to standard lead screws. Heavy Load Ball Screws: Designed with larger ball diameters and robust nut designs, these ball screws can handle significant static and dynamic loads. They are used in heavy-duty machinery like injection moulding machines, forging presses, and large industrial robots. Ball Splines: While technically not ball screws, ball splines are closely related linear motion components that transmit torque while allowing linear movement. They consist of a splined shaft and a nut containing recirculating balls. Ball splines are used in applications requiring both linear motion and rotational power transmission, such as industrial robots and transfer mechanisms.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Ball Screws in India: A Comprehensive Guide fo...

2025-04-09T03:09:30

Ball Screws in India: A Comprehensive Guide for Buyers in 2025 Ball screws are precision mechanical components that convert rotary motion into linear motion, or vice versa, with high efficiency and accuracy. They are integral to various industrial machinery and automation systems, playing a crucial role in applications demanding precise positioning, high load capacity, and smooth operation. For businesses and engineers in India seeking to procure ball screws in 2025, a thorough understanding of the different types, key specifications, selection criteria, and the evolving Indian market landscape is paramount for making informed purchasing decisions. This comprehensive article serves as a valuable resource for buyers in India. It provides in-depth information and incorporates relevant SEO keywords to enhance its online visibility and reach the target audience. Understanding the Fundamentals of Ball Screws A ball screw assembly primarily consists of four main components: Screw Shaft: A precision-machined steel shaft with a helical groove (ball track) ground along its length. Nut: A housing with internal helical grooves that match the screw shaft's grooves. It contains the ball bearings. Ball Bearings: Precision steel balls that circulate between the grooves of the screw shaft and the nut, providing the rolling contact that minimizes friction. Ball Return Mechanism: A system within the nut that guides the balls back to the track's starting point after they have travelled the length of the nut. Common types include internal and external return tubes, deflectors, and end caps. The rolling motion of the balls between the screw and the nut significantly reduces friction compared to traditional lead screws, resulting in higher efficiency, lower power consumption, and reduced wear. Types of Ball Screws Available in the Indian Market (2025) The Indian market in 2025 offers a diverse range of ball screw types to cater to the specific needs of various industries. Key types include: Ground Ball Screws: These are manufactured by precision grinding the ball tracks on both the screw shaft and the nut. They offer the highest accuracy, repeatability, and preload capabilities, making them ideal for high-precision applications such as CNC machine tools, measuring instruments, and semiconductor manufacturing equipment. Ground ball screws are typically more expensive due to the intricate manufacturing process. Rolled Ball Screws: These are produced by a rolling process, which is more cost-effective than grinding. While they offer good accuracy and load capacity, their precision levels are generally lower than ground ball screws. Rolled ball screws are widely used in general automation equipment, packaging machinery, and less demanding positioning systems where cost-effectiveness is a significant factor. Miniature Ball Screws: These compact and lightweight ball screws are designed for applications with limited space and weight constraints, such as small robotic arms, medical devices, and precision instruments. They offer high precision in a small form factor. High Lead Ball Screws: These screws have a larger helix angle, resulting in a greater linear travel per revolution of the screw shaft. They are suitable for applications requiring high-speed and rapid traverses, such as pick-and-place robots and high-speed automation systems. However, they may have lower load capacity compared to standard lead screws. Heavy Load Ball Screws: Designed with larger ball diameters and robust nut designs, these ball screws can handle significant static and dynamic loads. They are used in heavy-duty machinery like injection moulding machines, forging presses, and large industrial robots. Ball Splines: While technically not ball screws, ball splines are closely related linear motion components that transmit torque while allowing linear movement. They consist of a splined shaft and a nut containing recirculating balls. Ball splines are used in applications requiring both linear motion and rotational power transmission, such as industrial robots and transfer mechanisms.

2025-04-09T03:09:30

Keywords

- 2025 offers

- india seeking

- length nut

- balls back

- nut providing

- precision grinding

- transfer mechanisms

- industrial robots

- transmit torque

- heavyduty machinery

- dynamic loads

- pickandplace robots

- rapid traverses

- weight constraints

- limited space

- generally lower

- load capacity

- rolling process

- expensive due

- highprecision applications

- diverse range

- indian market

- indian market 2025

- end caps

- rolling contact

- online visibility

- indepth information

- valuable resource

- smooth operation

- crucial role

- industrial machinery

- vice versa

- splined shaft

- rolling motion

- screw shaft

- precision instruments

- precision levels

- applications requiring

- high efficiency

- comprehensive guide

- 2025 ball screws

- ball screws

- linear motion

- ball tracks

- offer high precision

- internal helical grooves

- applications requiring highspeed

- screw shafts grooves

- ball screw types

- offer good accuracy

- lightweight ball screws

- ground ball screws

- procure ball screws

- robust nut designs

- nut common types

- target audience understanding

- precisionmachined steel shaft

- convert rotary motion

- highest accuracy repeatability

- precision mechanical components

- larger ball diameters

- allowing linear movement

- greater linear travel

- tracks starting point

- comprehensive article serves

- rotational power transmission

- handle significant static

- highspeed automation systems

- demanding positioning systems

- preload capabilities making

- industries key types

- reduced wear types

- automation systems playing

Search on this site

Have any question or need any business consultation?

Have any question or need any business consultation?

Contact UsIBK ENGINEERS Pvt Ltd

Submit Your Enquiry