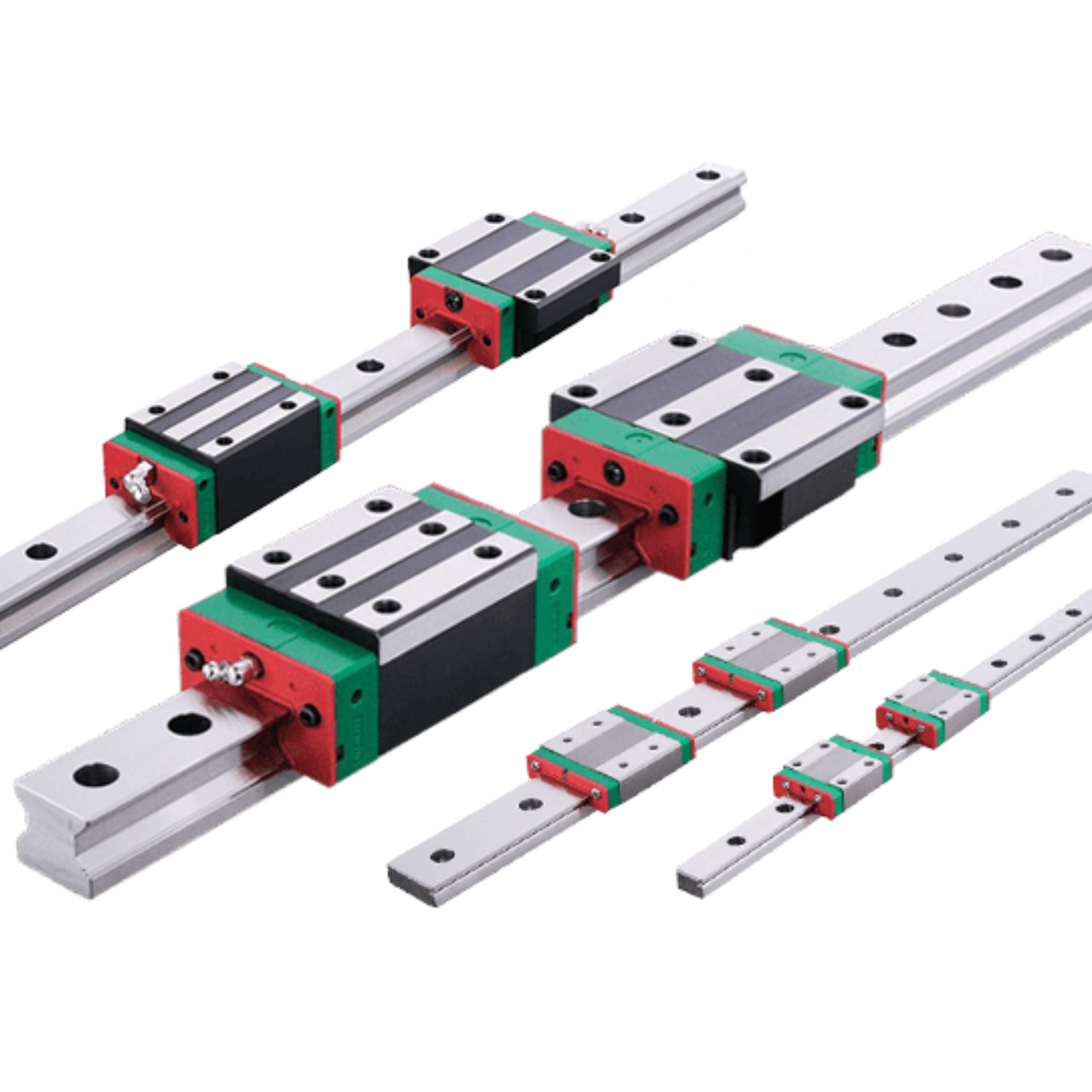

Precision Power: Hiwin Spares for Stone Cutting Machines The stone cutting industry demands unwavering precision and robust performance. To achieve this, the heart of many high-quality stone cutting machines lies in their linear motion systems. Among the leading manufacturers of these critical components, Hiwin stands out for its reliability and accuracy. This article delves into the essential Hiwin spares – linear guides, LM rails, and ball screws – and their pivotal role in maintaining the efficiency and longevity of stone cutting machinery. The Foundation of Accuracy: Hiwin Linear Guides and LM Rails Hiwin linear guides, often paired with their corresponding LM (Linear Motion) rails, provide the foundational support for smooth and precise movement within a stone cutting machine. These components work in tandem to ensure the cutting head or worktable traverses with minimal friction and maximum accuracy. Unwavering Stability: Hiwin linear guides are engineered with precision ball bearings that roll along hardened and ground LM rails. This design minimizes vibration and deflection, crucial when dealing with heavy stone materials and intricate cutting patterns. Replacing worn or damaged linear guides and rails with genuine Hiwin spares ensures the machine retains its original stability, preventing inaccuracies in cuts and potential damage to the workpiece. Enhanced Precision: The tight tolerances and smooth movement facilitated by Hiwin linear guides directly translate to higher cutting precision. Whether it's straight cuts, intricate curves, or complex profiling, maintaining the integrity of these components is paramount. Swapping out worn guides and rails eliminates play and ensures the cutting tool follows the programmed path accurately. Increased Lifespan: The demanding environment of stone cutting, with its dust and abrasive particles, can take a toll on linear motion components. Regular inspection and timely replacement with genuine Hiwin spares can significantly extend the lifespan of the machine. Hiwin's commitment to quality materials and manufacturing processes ensures that their replacement guides and rails offer the same durability and resistance to wear as the originals. The Driving Force: Hiwin Ball Screws Hiwin ball screws are the electromechanical actuators responsible for converting rotary motion into precise linear motion. They play a crucial role in controlling the feed rate and depth of cut in stone cutting machines. Accurate Positioning: Hiwin ball screws are known for their high accuracy and repeatability. This is essential for achieving consistent cutting depths and intricate designs. Replacing a worn or damaged ball screw with a genuine Hiwin spare ensures that the machine maintains its precise positioning capabilities, leading to higher quality finished products and reduced material waste. Efficient Power Transmission: The rolling contact between the ball bearings and the screw shaft in a Hiwin ball screw minimizes friction, resulting in efficient power transmission. This translates to lower energy consumption and reduced heat generation. Replacing a worn ball screw can restore this efficiency, leading to cost savings and improved machine performance. Smooth and Reliable Operation: A properly functioning ball screw ensures smooth and reliable movement of the cutting head or worktable. Replacing a damaged or worn ball screw eliminates jerky movements and potential backlash, contributing to a more stable and predictable cutting process. Hiwin's rigorous quality control ensures that their replacement ball screws meet the same high standards of smooth operation as the original components. The Importance of Genuine Hiwin Spares While aftermarket alternatives may seem appealing, opting for genuine Hiwin spares for linear guides, LM rails, and ball screws is crucial for several reasons: Guaranteed Compatibility: Genuine Hiwin spares are designed and manufactured to the exact specifications of the original components, ensuring seamless integration and optimal performance. Uncompromised Quality: Hiwin's reputation for quality is built on stringent manufacturing processes and high-grade materials. Genuine spares uphold this standard, offering superior durability and reliability. Preserving Machine Performance: Using genuine spares ensures that the machine operates at its intended performance levels, maintaining accuracy, efficiency, and longevity. Warranty Protection: Using non-genuine spares may void the machine manufacturer's warranty, potentially leading to higher repair costs in the long run. Conclusion In the demanding world of stone cutting, the precision and reliability of linear motion systems are paramount. Hiwin linear guides, LM rails, and ball screws are critical components that contribute significantly to the accuracy, efficiency, and lifespan of stone cutting machines. Investing in genuine Hiwin spares when replacements are necessary is not just a repair.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Precision Power: Hiwin Spares for Stone Cutting...

2025-05-03T04:25:46

Precision Power: Hiwin Spares for Stone Cutting Machines The stone cutting industry demands unwavering precision and robust performance. To achieve this, the heart of many high-quality stone cutting machines lies in their linear motion systems. Among the leading manufacturers of these critical components, Hiwin stands out for its reliability and accuracy. This article delves into the essential Hiwin spares – linear guides, LM rails, and ball screws – and their pivotal role in maintaining the efficiency and longevity of stone cutting machinery. The Foundation of Accuracy: Hiwin Linear Guides and LM Rails Hiwin linear guides, often paired with their corresponding LM (Linear Motion) rails, provide the foundational support for smooth and precise movement within a stone cutting machine. These components work in tandem to ensure the cutting head or worktable traverses with minimal friction and maximum accuracy. Unwavering Stability: Hiwin linear guides are engineered with precision ball bearings that roll along hardened and ground LM rails. This design minimizes vibration and deflection, crucial when dealing with heavy stone materials and intricate cutting patterns. Replacing worn or damaged linear guides and rails with genuine Hiwin spares ensures the machine retains its original stability, preventing inaccuracies in cuts and potential damage to the workpiece. Enhanced Precision: The tight tolerances and smooth movement facilitated by Hiwin linear guides directly translate to higher cutting precision. Whether it's straight cuts, intricate curves, or complex profiling, maintaining the integrity of these components is paramount. Swapping out worn guides and rails eliminates play and ensures the cutting tool follows the programmed path accurately. Increased Lifespan: The demanding environment of stone cutting, with its dust and abrasive particles, can take a toll on linear motion components. Regular inspection and timely replacement with genuine Hiwin spares can significantly extend the lifespan of the machine. Hiwin's commitment to quality materials and manufacturing processes ensures that their replacement guides and rails offer the same durability and resistance to wear as the originals. The Driving Force: Hiwin Ball Screws Hiwin ball screws are the electromechanical actuators responsible for converting rotary motion into precise linear motion. They play a crucial role in controlling the feed rate and depth of cut in stone cutting machines. Accurate Positioning: Hiwin ball screws are known for their high accuracy and repeatability. This is essential for achieving consistent cutting depths and intricate designs. Replacing a worn or damaged ball screw with a genuine Hiwin spare ensures that the machine maintains its precise positioning capabilities, leading to higher quality finished products and reduced material waste. Efficient Power Transmission: The rolling contact between the ball bearings and the screw shaft in a Hiwin ball screw minimizes friction, resulting in efficient power transmission. This translates to lower energy consumption and reduced heat generation. Replacing a worn ball screw can restore this efficiency, leading to cost savings and improved machine performance. Smooth and Reliable Operation: A properly functioning ball screw ensures smooth and reliable movement of the cutting head or worktable. Replacing a damaged or worn ball screw eliminates jerky movements and potential backlash, contributing to a more stable and predictable cutting process. Hiwin's rigorous quality control ensures that their replacement ball screws meet the same high standards of smooth operation as the original components. The Importance of Genuine Hiwin Spares While aftermarket alternatives may seem appealing, opting for genuine Hiwin spares for linear guides, LM rails, and ball screws is crucial for several reasons: Guaranteed Compatibility: Genuine Hiwin spares are designed and manufactured to the exact specifications of the original components, ensuring seamless integration and optimal performance. Uncompromised Quality: Hiwin's reputation for quality is built on stringent manufacturing processes and high-grade materials. Genuine spares uphold this standard, offering superior durability and reliability. Preserving Machine Performance: Using genuine spares ensures that the machine operates at its intended performance levels, maintaining accuracy, efficiency, and longevity. Warranty Protection: Using non-genuine spares may void the machine manufacturer's warranty, potentially leading to higher repair costs in the long run. Conclusion In the demanding world of stone cutting, the precision and reliability of linear motion systems are paramount. Hiwin linear guides, LM rails, and ball screws are critical components that contribute significantly to the accuracy, efficiency, and lifespan of stone cutting machines. Investing in genuine Hiwin spares when replacements are necessary is not just a repair.

2025-05-03T04:25:46

Keywords

- accuracy efficiency

- efficiency leading

- high accuracy

- crucial role

- deflection crucial

- critical components

- original components

- components work

- contribute significantly

- demanding world

- exact specifications

- appealing opting

- aftermarket alternatives

- smooth operation

- high standards

- reliable operation

- cost savings

- rolling contact

- feed rate

- quality materials

- significantly extend

- timely replacement

- abrasive particles

- demanding environment

- paramount swapping

- tight tolerances

- minimal friction

- worktable traverses

- foundational support

- pivotal role

- article delves

- leading manufacturers

- robust performance

- rails offer

- reliable movement

- replacement guides

- worn guides

- machine operates

- machine maintains

- machine retains

- ball screws

- cutting tool

- cutting head

- worktable replacing

- potential damage

- screw shaft

- nongenuine spares

- precise movement

- ball bearings

- stone cutting

- worn ball screw

- rails eliminates play

- smooth movement facilitated

- damaged ball screw

- precision ball bearings

- stone cutting machine

- damaged linear guides

- higher cutting precision

- higher repair costs

- longevity warranty protection

- complex profiling maintaining

- stone cutting machinery

- stone cutting machines

- heavy stone materials

- genuine spares ensures

- ground lm rails

- manufacturing processes ensures

- machine hiwins commitment

- potential backlash contributing

- intricate designs replacing

- precise linear motion

- workpiece enhanced precision

- genuine hiwin spares

- long run conclusion

- stringent manufacturing processes

- lower energy consumption

- efficient power transmission

- converting rotary motion

- electromechanical actuators responsible

- design minimizes vibration

- linear motion systems

Search on this site

Have any question or need any business consultation?

Have any question or need any business consultation?

Contact UsIBK ENGINEERS Pvt Ltd

Submit Your Enquiry